GHG Reduction Initiatives

GC has introduced numerous projects that reduce greenhouse gas emissions (scope 1 and 2) in order to lessen climate change impact. These efforts align with the energy management and climate change strategy by enhancing operational efficiency and applying technology to reduce energy, reduce greenhouse gas emission, utilization of renewable or low-carbon energy sources. exploration of Carbon Capture and Storage (CCS) technology alongside the utilization of carbon capture technology.

Energy Conservation Projects

GC has implemented a total of 93 new energy conservation projects by enhancing energy efficiency in production processes through the application of innovation and technology while raising employee awareness to enable efficient use of energy and take part in fostering a corporate culture of energy conservation

Overall Performance of New Energy Conservation Projects in 2024

| Investment (million baht) | 287 |

| Reduction of Energy Consumption (GJ per year*) | 0.8 |

| Reduction of GHG Emissions (tons of CO2 equivalent per year**) | 58,078 |

| Reduction of Costs (million baht*) | 328 |

| Equivalent to Planting Trees (million trees per year***) | 6.1 |

Remark:

* Potential net GHG reduction per annum

** Estimated GHG reduction from project based on GC’s business plan

*** Based on the Thailand Greenhouse Gas Management Organization (TGO)’s data whereby the carbon sequestration capacity of forest plants is 0.95 tCO2 /rai/year with a density of 100 trees/rai

Recovery Heat from Benzene Rundown, Heavy Aromatic Overhead

GC has installed a heat exchanger in the production process of Aromatics 2 Plant, whereby benzene from the distillation column is reintroduced into the newly installed heat exchanger. Heat from benzene is exchanged with heavy aromatics to reduce heat loss and enable heat reutilization. This has contributed to reducing energy consumption and the company’s costs.

| Investment (million baht) | 49 |

| Reduction of Energy Consumption (GJ per year*) | 63,606 |

| Reduction of GHG Emissions (tons of CO2 equivalent per year**) | 3,381 |

| Reduction of Costs (million baht*) | 27.1 |

| Equivalent to Planting Trees (million trees per year***) | 0.4 |

Remark:

* Potential net GHG reduction per annum

** Estimated GHG reduction from project based on GC’s business plan

*** Based on the Thailand Greenhouse Gas Management Organization (TGO)’s data whereby the carbon sequestration capacity of forest plants is 0.95 tCO2 /rai/year with a density of 100 trees/rai

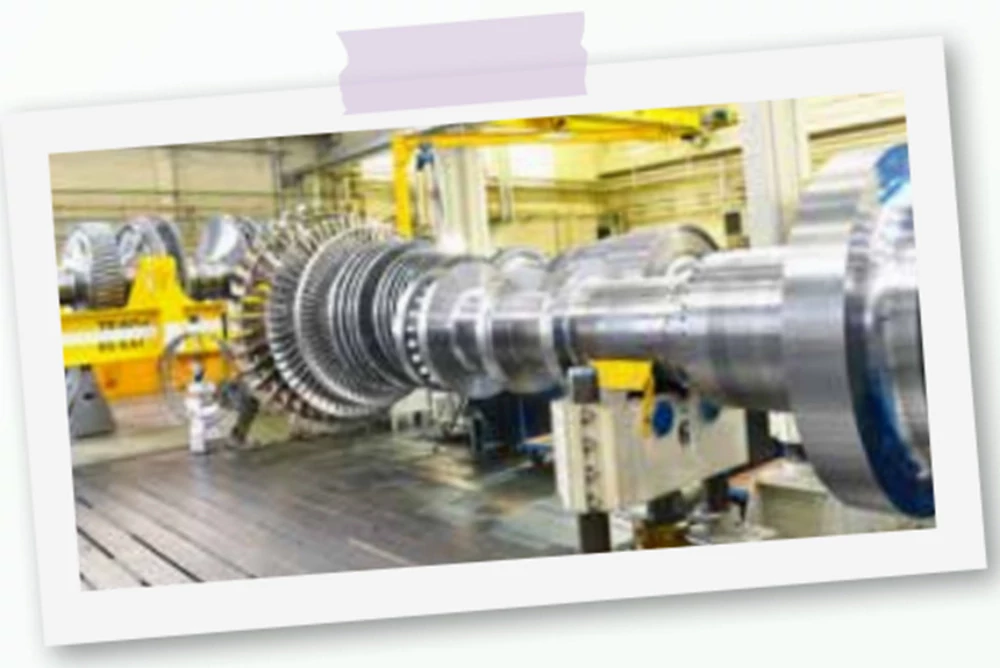

Gas Turbine Generator’s Advance Gas Path (AGP) Improvement

GC has installed Advanced Gas Path (AGP) at the Gas Turbine Generator (GTG) in the Utility Plant to minimize the GTG’s energy consumption, which has contributed to energy and cost reduction.

| Investment (million baht) | 71 |

| Reduction of Energy Consumption (GJ per year*) | 60,489 |

| Reduction of GHG Emissions (tons of CO2 equivalent per year**) | 6,608 |

| Reduction of Costs (million baht*) | 29.8 |

| Equivalent to Planting Trees (million trees per year***) | 0.7 |

Remark:

* Potential net GHG reduction per annum

** Estimated GHG reduction from project based on GC’s business plan

*** Based on the Thailand Greenhouse Gas Management Organization (TGO)’s data whereby the carbon sequestration capacity of forest plants is 0.95 tCO2 /rai/year with a density of 100 trees/rai

Optimization Compressor by Turning Surge Control Line

GC has optimized compressor efficiency in Olefins 1 Plant by adjusting surge control value in the compressor system to enhance efficiency, cut down on unnecessary energy consumption, and reduce company costs.

| Reduction of Energy Consumption (GJ per year*) | 84,328 |

| Reduction of GHG Emissions (tons of CO2 equivalent per year**) | 3,641 |

| Reduction of Costs (million baht*) | 39.1 |

| Equivalent to Planting Trees (million trees per year***) | 0.4 |

Remark:

* Potential net GHG reduction per annum

** Estimated GHG reduction from project based on GC’s business plan

*** Based on the Thailand Greenhouse Gas Management Organization (TGO)’s data whereby the carbon sequestration capacity of forest plants is 0.95 tCO2 /rai/year with a density of 100 trees/rai

Renewable Energy

In 2024, GC implemented a total of three renewable energy projects, including the expansion of solar energy generation systems and the utilisation of biogas as a substitute for fossil fuels.

| Reduction of Energy Consumption (GJ per year*) | 70 |

| Reduction of GHG Emissions (tons of CO2 equivalent per year**) | 21,766 |

| Reduction of Costs (million baht*) | 4 |

| Equivalent to Planting Trees (million trees per year***) | 2.3 |

Remark:

* Potential net GHG reduction per annum

** Estimated GHG reduction from project based on GC’s business plan

*** Based on the Thailand Greenhouse Gas Management Organization (TGO)’s data whereby the carbon sequestration capacity of forest plants is 0.95 tCO2 /rai/year with a density of 100 trees/rai

Solar Energy

In 2024, GC expanded our solar energy project through the installation of 1.2 MW Solar Rooftop system at the Aromatics 2 Plant and 0.6 MW Solar Floating system at the InnoPlus Solution Center. GC also collaborated with partners to produce 8 MW equivalent of floating solar pontoons to generate electricity for companies in the Eastern Seaboard Industrial Estate in Rayong province. In this regard, InnoPlus high-density polyethylene (HDPE) pellets are used in the production of SUNTARATM floats, which feature exceptional strength.

| Energy Production (MWh per year*) | 2,848 |

| Reduction of GHG Emissions (tons of CO2 equivalent per year**) | 1,309 |

| Reduction of Costs (million baht*) | 4 |

| Equivalent to Planting Trees (million trees per year***) | 0.1 |

Remark:

* Potential net GHG reduction per annum

** Estimated GHG reduction from project based on GC’s business plan

*** Based on the Thailand Greenhouse Gas Management Organization (TGO)’s data whereby the carbon sequestration capacity of forest plants is 0.95 tCO2 /rai/year with a density of 100 trees/rai

Biogas

Global Green Chemicals Public Company Limited (GGC), a subsidiary of GC, signed a contract to purchase biogas from Thai Eastern Biopower Company Limited (TEBP) with a maximum initial volume of 34,000 cubic meters per day to replace the use of fossil fuel in steam boilers and hot oil boilers in GGC2 site, which has contributed to the continuous decline in greenhouse gas emissions from the production process as well as company costs.

| Investment (million baht) | 70 |

| Reduction of GHG Emissions (tons of CO2 equivalent per year*) | 20,457 |

| Equivalent to Planting Trees (million trees per year**) | 2.2 |

Remark:

* Estimated GHG reduction from project based on GC’s business plan

** Based on the Thailand Greenhouse Gas Management Organization (TGO)’s data whereby the carbon sequestration capacity of forest plants is 0.95 tCO2 /rai/year with a density of 100 trees/rai

Carbon Capture and Storage (CCS) Study in collaboration with PTT Group

GC, in collaboration with the PTT Group, has undertaken a study on a Carbon Capture and Storage (CCS) project in Eastern Thailand to help reduce the country’s greenhouse gas emissions. This initiative, known as the Eastern Thailand Carbon Capture and Storage Hub (CCS Hub), includes the development of a project study report (White Paper), which has been submitted to the government on behalf of the PTT Group. The proposal outlines a national pilot project for the application of carbon capture, utilisation, and storage (CCUS) technologies, with operations expected to commence in 2034. Currently, GC is exploring alternative emerging carbon capture technologies to compare with existing solutions in terms of efficiency and cost. The study also includes an assessment of feasibility and potential for future investment decisions.

Framework for Industry’s Net-Zero Transition

GC, together with the Petrochemical Industry Club of the Federation of Thai Industries (FTIPC), has proposed a decarbonization guideline for Thailand’s petrochemical sector through the “Framework for Industry’s Net-Zero Transition” project, under the Clean Energy Finance & Investment Mobilization (CEFIM) initiative and the Organization for Economic Cooperation and Development (OECD). As part of this effort, GC Carbon Capture and Storage (CCS) project is being advanced and will be assessed and included in the OECD project report. The findings will be submitted to relevant government agencies to support coordination and further implementation.

Nature-Based Solutions

GC has taken action to conserve and restore natural resources in collaboration with government agencies, the private sector, and local communities. It aims to offset one million tonnes of carbon dioxide equivalent (tCO2e) by 2050 through three key approaches: 1) Reforestation projects, including both terrestrial and mangrove forests, 2) Forest conservation initiatives, and 3) The purchase of removal-type carbon credits. In addition, GC is exploring other potential initiatives, such as alternate wetting and drying (AWD) rice cultivation. These efforts not only contribute to climate mitigation but also enhance biodiversity, supporting plant and animal species and entire ecosystems, while generating additional income for local communities through inclusive participation in forest planting, maintenance, and restoration.

As a result of diverse greenhouse gas emissions reduction projects, GC’s cumulative greenhouse gas emissions reduction is as follows:

Cumulative greenhouse gas emissions reduction between 2022-2024:

tons CO2 equivalent